无标题文档

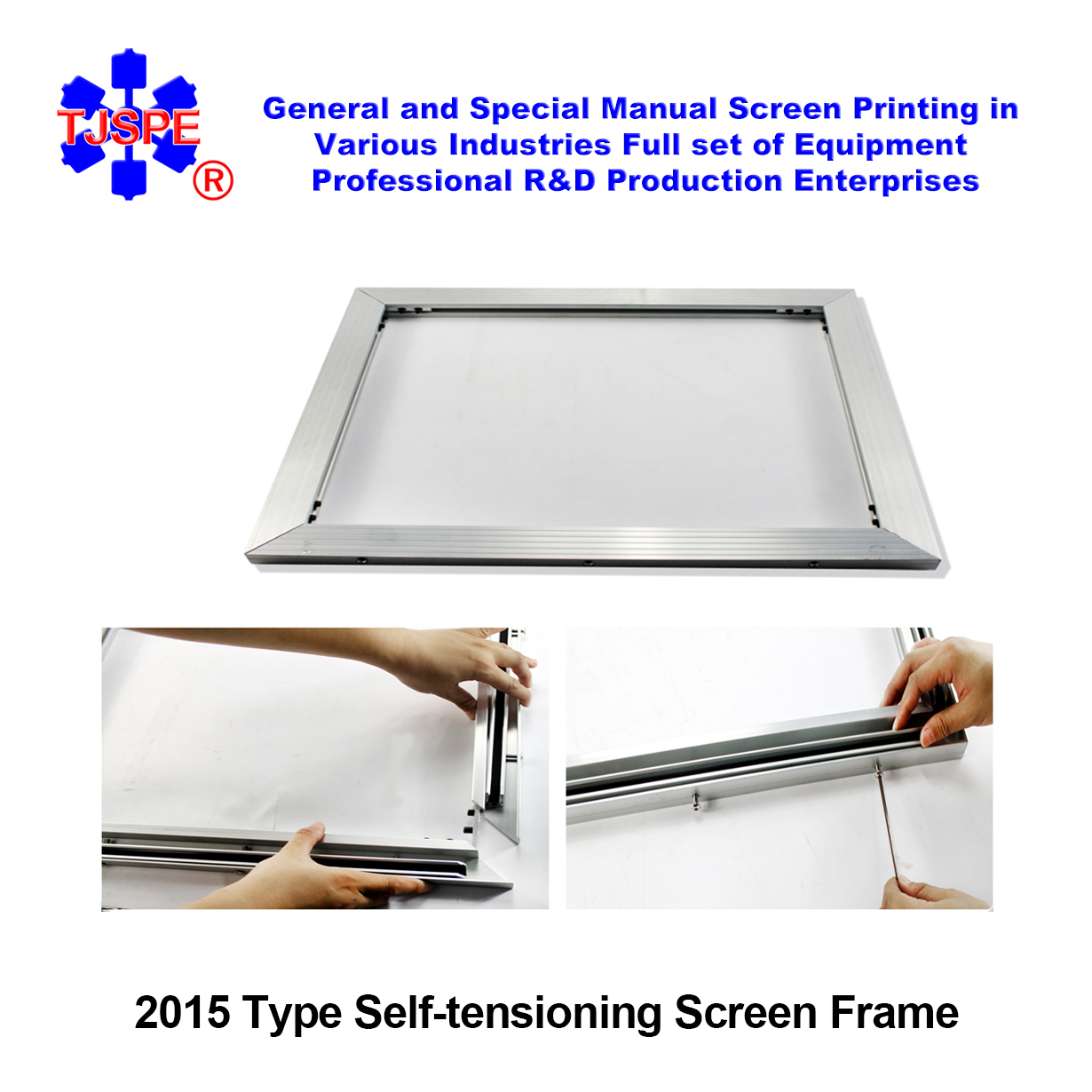

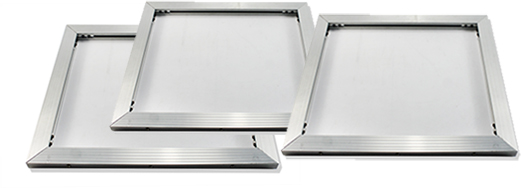

2015 Type Self-tensioning Screen Frame

2015 type self-tensioning screen frame is the latest invention of our company.

the new screen printing frame to compare the old one, new self-stretching frame much simple and does not need glues.

Any combination can be into any size of screen frame according to needs and repeated use, product of screen printing would be installed repeatedly, assemble stretching of an arbitrary size of screen frame only needs 3-5 minutes, after tensioning-frame stretch the frame just like the traditional metal or wooden frame (you also can put emulsion print and printing.with electric screwdriver install more faster and more efficient), stretched screen frame and ordinary frame without any difference.

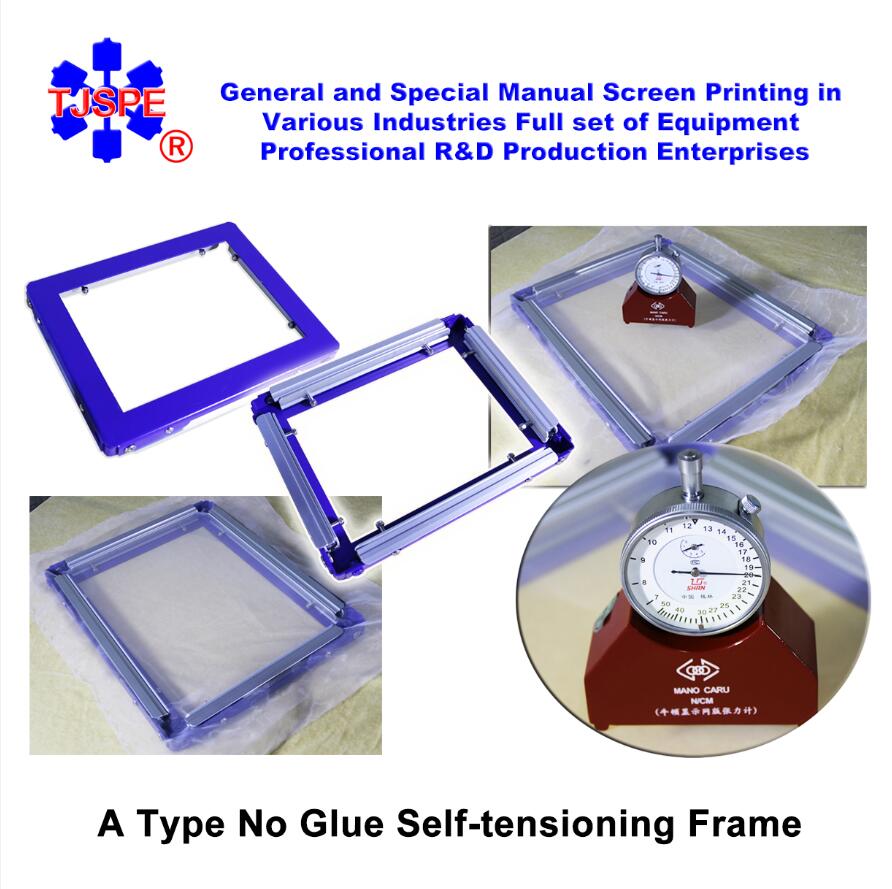

The self-stretching frame using a special aluminum material, the frame size 43*25 mm. special structural design, strength is higher than normal aluminum, 1.1 kgs weight per meter, 40*50cm inner diameter the weight is 2.88 kg, completely suitable for screen printing need.

The main features:

-

Replace the hand Screen Stretcher ,the self-tensioing frame can stretch mesh directly without any glue or other staffs.

-

The tension equality between the edge, each edge according to the allocated length 2-4 tension points, through to rally the uniform operation completely to enable the screen tension and requirements.

-

we can use the stretched frame to make plate ,print just like using the traditional metal or wood frame.Users can use the frame to print directly.

-

The repeated use of the finished silk screen mesh (main monochrome), the frame only need a set of stretch clamp, and it can finish stretching screen mesh. The screen frame is the same with traditional screen frame when we take down the one.

-

When the user need to use the mesh again , just install the mesh to the frame.

-

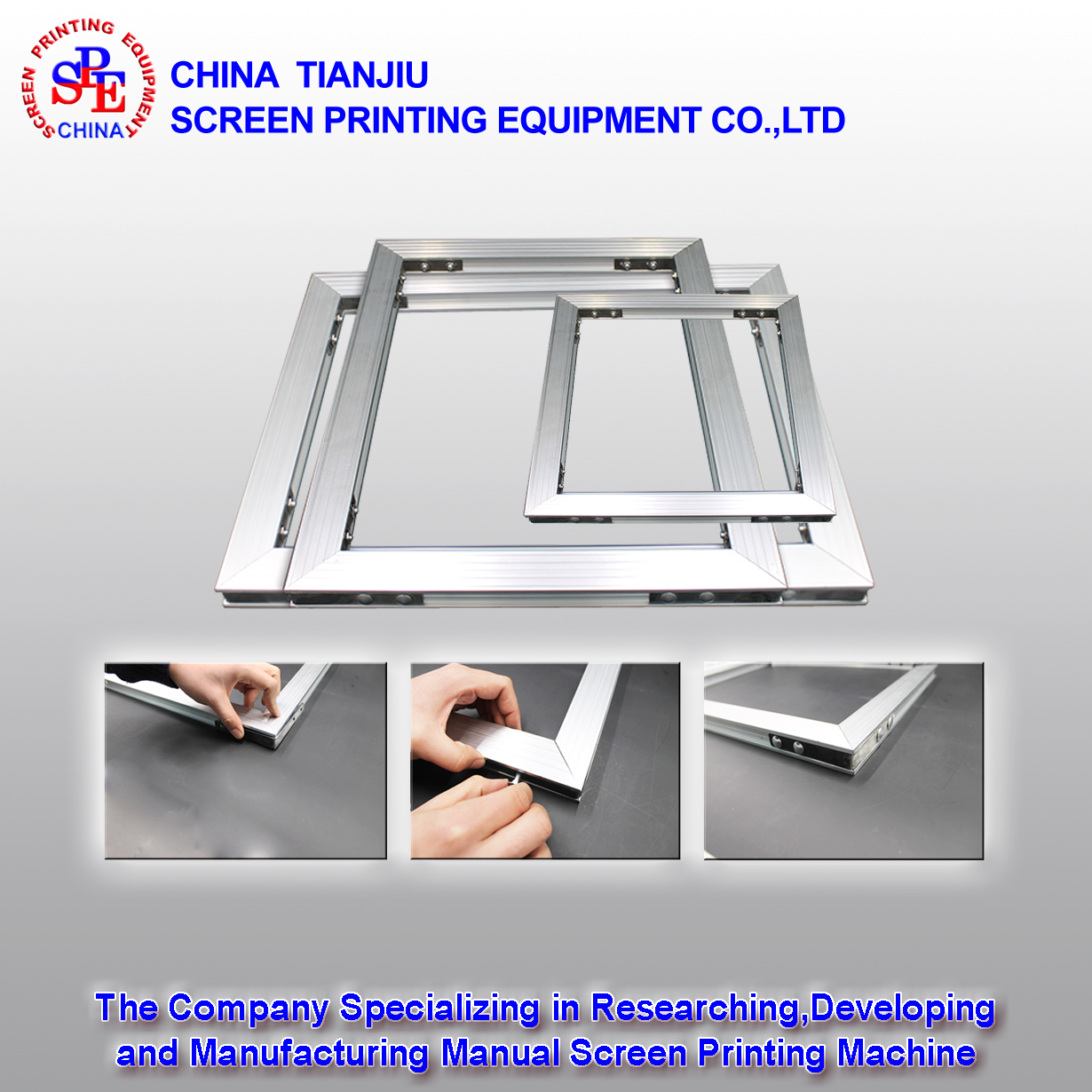

The screen frame edge can be custom size, different size frame strips can be composed of various sizes of the screen frame, and it can adapt to different size designs of different screen frame need.

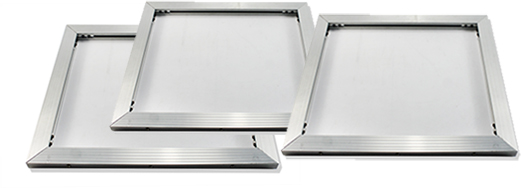

Such as the company's standard configuration TW700; TW600; TW500; TW400, TW300 five kinds of size of the self-tensioning screen frame edge each 4 can be combined into:

70*60 (CM) 70*70(CM); 70*50(CM); 70*40(CM); 70*30(CM)

60*60(CM); 60*50(CM); 60*40(CM); 60*30(CM);

50*40(CM); 50*30(CM); 50*50(CM);

40*40(CM); 40*30(CM); 30*30(CM);

there are fifteen different sizes of the self-tensioning screen frames, users only need to combine any size screen frame according to the design.

-

the self-tensioning screen frame all adopt aluminum alloy, stainless steel and alloy nickel plating material;washable, corrosion resistant, no rust.

-

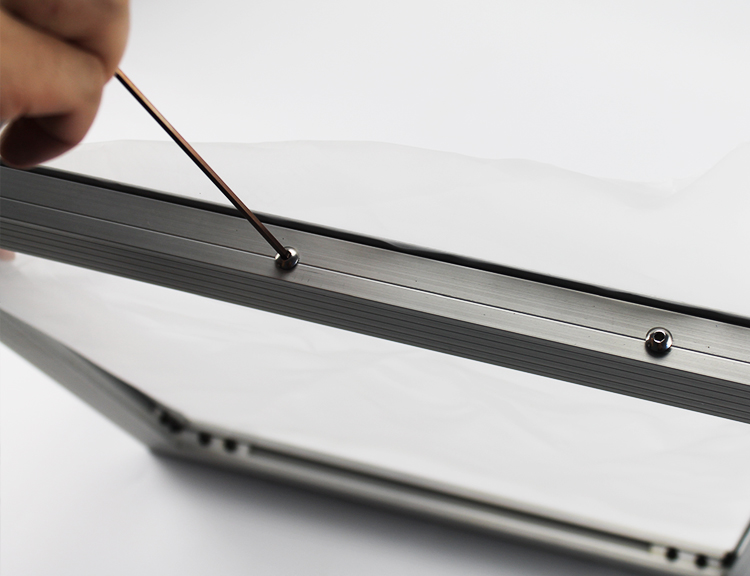

the self-tensioning screen frame only needs M3 inner Allen wrench, user do not need to purchase other materials or tools to stretch mesh , make plate anad print.

Special notes:

The frame material can custom any size below 1.4meter (each single edge over 1.4 meter , the screen frame will be a bit out of shape, affect the screen tension), the price can be confirmed according to the special size.

Using methods of the 2015 self-tensioning frame

1.Choose different sizes frame material according to need.

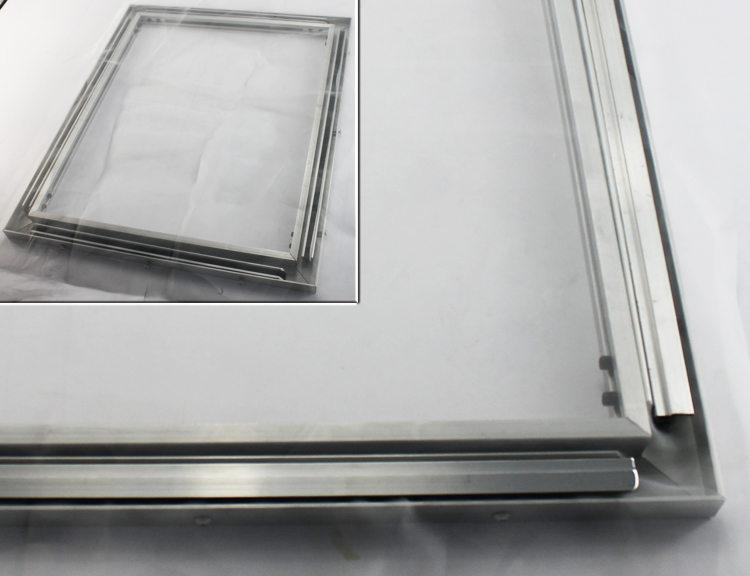

2.Insert the 4 pcs corner connector to the groove on the stripe to connect them .

3.Fix the screen frame by socket head wrench.

4.Loose the outside screws of stretching strip,pull the press mesh aluminium strip to the outermost side of frame.

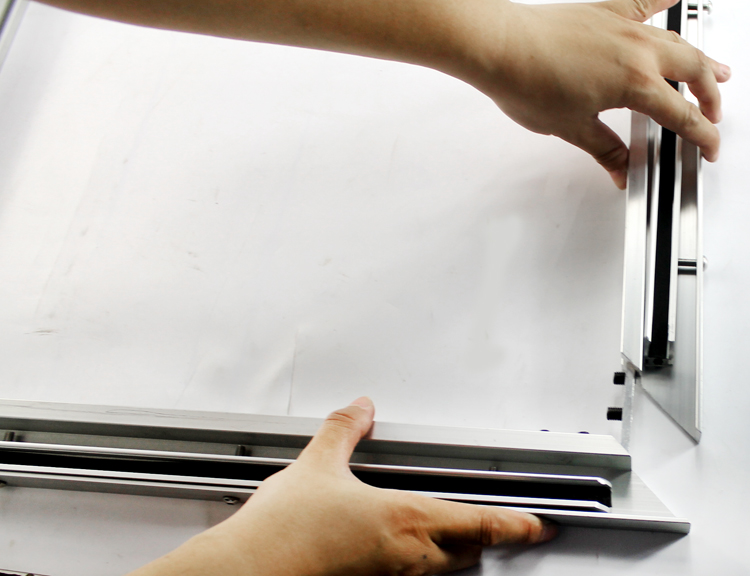

5.Put the mesh evenly on the screen frame,buckle the mesh to the groove by aluminium strip,

simultaneously buckle in from both sides, try to tension the mesh as much as possible.

6.Pull the tension point by socket head wrench uniformly,stretch the mesh to proper tension.

7.Mesh stretching finished

Coating the emulsion , exposing the plate:It is the same with the traditional cleaning, drying, coating the emulsion (film).

Print and clean the screen frame: it is exactly the same With the traditional screen printing and screen cleaning operation process.

Take off the mesh: after cleaning up the used screen frame and dried ,loose the outer screws ,open the aluminium strip,and take out the mesh from the groove , the mesh can be take out completely.

Keep the mesh :as for the removed mesh has not dry, keep it after natural drying or drying.

Install the mesh with design, operation method is the same with stretching mesh.

Compared with the traditional screen printing stretching mesh

1.From slef-tensioning speed efficiency and environmental protection:

The traditional frame use glue making a aluminum alloy screen need 1-2 hours, proficient operation 2015 type self-tensioning screen frame of the same frame only needs 3-5 minutes, 1 hour at least stretch 20 screen frames, improve the efficiency of 20-30 times; such as in a cold environment, the traditional viscoplastic frame time will be longer; and the universal screen frame is not affected by any of the effect of environmental temperature.Change the screen frame for without any adhesive and shoot nail can be completely avoided due to glue dripping on the screen by screen and void; glue smell caused by indoor environmental pollution.

2.From the material cost comparison:

Such as our company's complete set of standard configuration TW700; TW600; TW500; TW400, TW300 five kinds of sizes of the net frame sides of each 4; can be any combination into fifteen different sizes of the frame.

Such as the purchase of welded aluminum alloy mesh box, 15 kinds of size each one, at least 1100 Chinese yuan, all fixed size, cannot change the size.

3.from the packaging transport volume comparison:

Above the configuration sets of complete (tw700; TW600; TW500; TW400, TW300 five size screen frame boundary the) weight for 16 kilograms; volume 0.025 cubic meters (outer packing size: 0.8*0.2*0.15); such as the same 15 size of traditional frame 9.8 kg; volume 0.1 cubic meters (size of the packing 0.71*0.71*0.19);. Volume is 4 times the self-tensioning screen frame.

4.From the application cost comparison:

The traditional screen frame is the purchase or fixed normally used size , once if need for special, product for the right size, need further customization, time-consuming, cost money, labor, and affects the working efficiency. At the same time, special size frame special use, many abandoned, resulting in waste. In particular, does not have the processing conditions of the silk screen for, for one or several screen frame had to online ordering, because special size or the number is too small, the seller also unwilling to processing or processing fees high. While online ordering caused by the delay, freight and other issues is more obvious.

Special size screen frame for special use after a lot of it was abandoned, resulting in waste, hesitate and leave useless.

The self-tensioning screen frame fundamentally solves this problem. No longer need for special size frame requires further processing and trouble; no longer need to worry about special size network frame uses after being abandoned ; just a few minutes to get themselves in need of special size of frame; also can be repeated to disassemble and assemble, permanent use.

5.From the practical cost comparison:

This self-tensioning screen frame screen mesh can be used repeated is the traditional screen incomparable. The self-tensioning screen frame special place is to end the use of mesh can be freely disassembled changed, the need to screen, can be directly installed on the frame, the different sizes of the network frame strips can be freely combined into various sizes of frame, a set of the box can be installed on an unlimited number of mesh, completely changed the traditional screen of a pattern of a screen making and preserving way.

Plate making technology of screen printing industry is the screen printing technology is the most important part, many buyers are interested in screen printing because of plate making process, more complex equipment, screen production time-consuming, consumption and site restrictions and flinch. Especially for small amount of printing buyers, often change pattern, color changing, every time the version to the screen with the screen frame is saved with, not only increases the cost of each edition of the, and for the preservation of these with the screen frame screen will occupy a lot of space, and these framed screen also carefully preserved, for any one of the buyers are a waste of the economy; resources idle. At the same time, as the need for were small number of screen printing products, and don't want to waste more time buyers in the screen printing plate making process, the ability to have the relatively inexpensive making screen, and can be carried out at any time printing screen, preservation and convenient products will enable more silk printing enthusiasts can according to their own preferences screen printing products.

To our screen outside processing screen buyers, especially the finished silk screen production of professional sellers, to purchase elf-tensioning screen frame buyers, only need to make professional plate making mesh can be, buyers received net product after directly installed in the elf-tensioning screen frame can be used. Regardless of the cost of plate making, transportation costs and other aspects can save a lot of costs. Because only the transport net, the security is unable to replace the traditional screen frame.

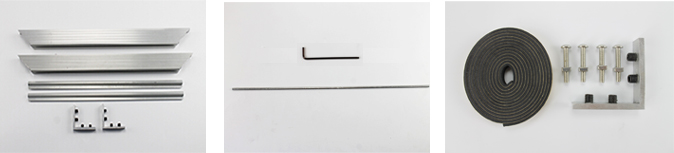

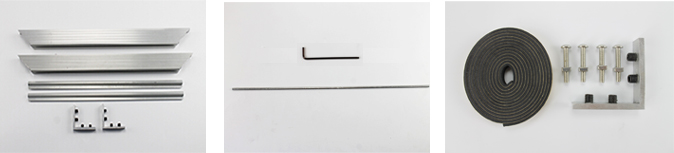

Self-tensioning screen frame material constitute

This self-tensioning screen frame and connecting parts all adopt special? aluminum alloy material.

All the screws are stainless steel.

Special tool only need one M3 inner allen wrench ; Purchasers will be given one set Germany A class allen wrench (screen frame above 50cm will be given one piece screw auxiliary rod )and some spare parts list is as follows:(one piece angle slot connector containing top screw; 6 units M5*30 stainless steel allen wrench screws with nut; Screw and nut will be equipped as spare parts ,sponge 1 roll).

Size and weight

Screen frame size(inner size cm/inch) |

2 pieces frame edging weight (kg/lb) |

30cm(12inch) |

0.94kg(2.1lb) |

40cm(16inch) |

1.28kg(2.8lb) |

50cm(20inch) |

1.60kg(3.5lb) |

60cm(24inch) |

1.92kg(4.2lb) |

70cm(28inch) |

2.24kg(4.9lb) |

Special tips:

This screen frame material can be customized any size below 1.4 m (unilateral more than 1.4 meters, net frame will be a bit out of shape, affect the screen tension), the specific price shall be determined separately according to the special size .

Buy any size and quantity screen frame above, one complete set of tools and accessories package will be given as gift.