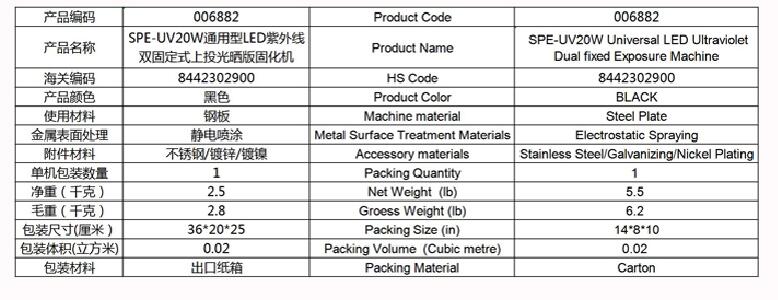

006882 SPE-UV20W Universal LED Ultraviolet Dual fixed Exposure Machine

This machine adopts 20 pieces LED lamp beads imported from Korea, the total power is 20W (equal to 200W ordinary ultraviolet lamp effect), the wavelength is 365nm , the exposure machine opening irradiation size is 140* 100mm; LED plate lamp beads can last 50,000 hours.

This machine is mainly used for exposing in screen printing, pad printing, bronzing, etc. It can also be used for curing products with wavelength of 365nm.

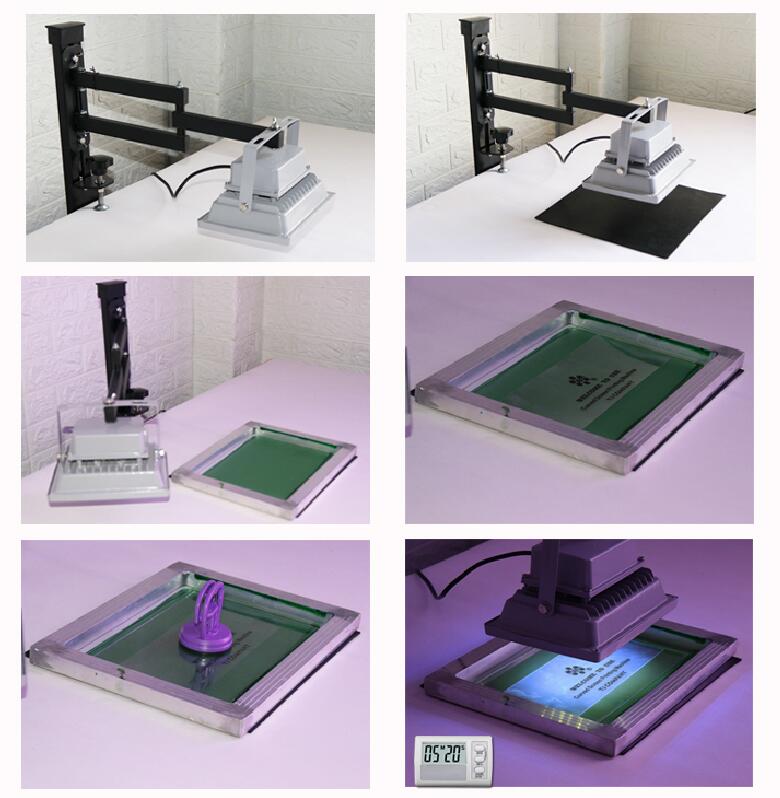

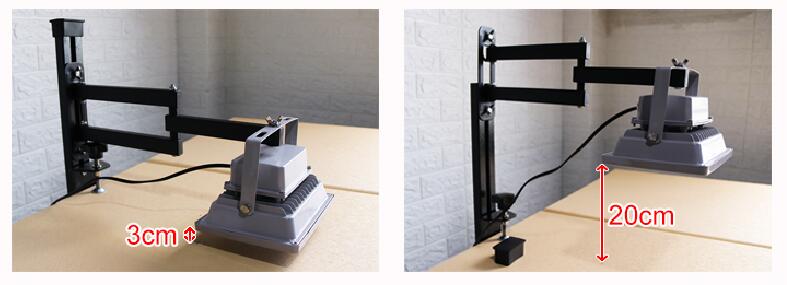

1,The light can rise and fall according to the need , the minimum distance from bottom of the machine to the surface of the desktop is 3 cm, the highest distance is 20 cm.

2,The machine can be installed in two ways: it can be directly clamped in the table edge with thickness of 1 cm to 5 cm ; It can also be fixed directly on the table with self - tapping.

3,the lamp can be expanded and rotated according to the need; Maximum extension distance is 36 cm (LED light center); The lamp holder can be rotated in 280 degrees. After using, the lamp holder can be rotated outside the table.

4,The machine adopts general voltage components, suitable for 90-230v voltage use.

5,In order to facilitate the user to exposing, the machine is additionally equipped with a flat 25*25 cm rubber plate with thickness of 2mm, a glass chuck and a countdown timer.

The operation methods is as follows:

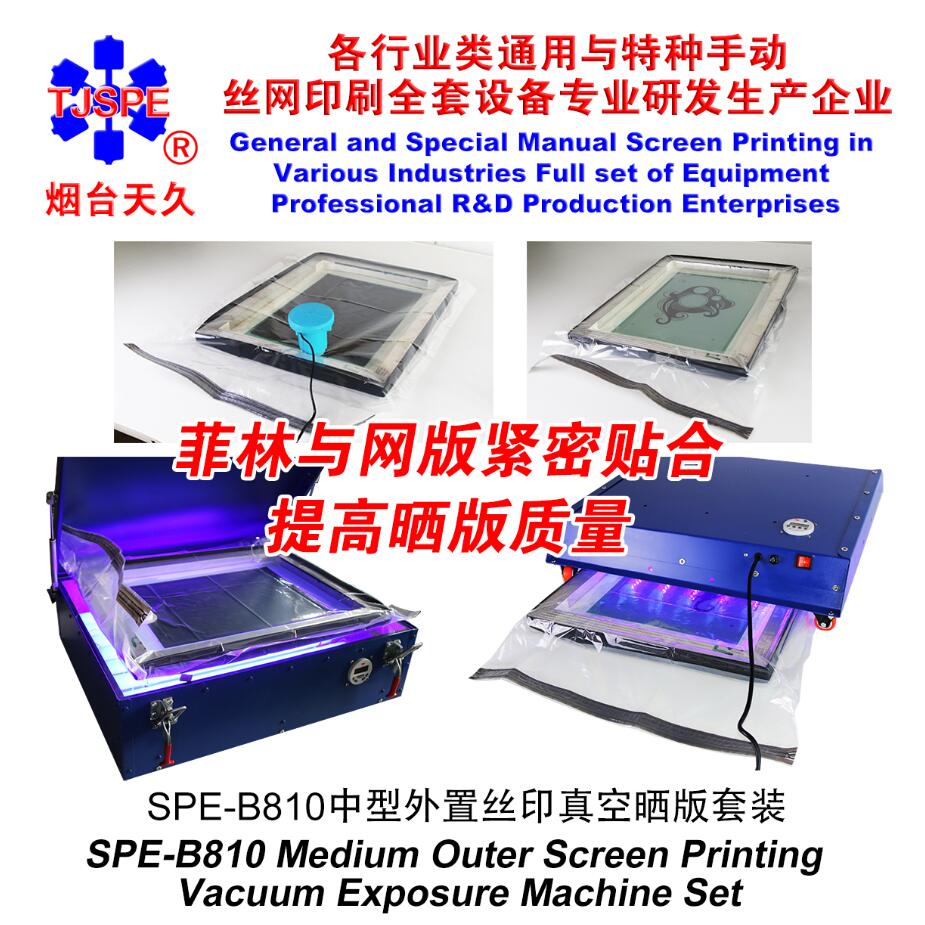

1,Spread the black rubber on a flat table;

2,Place the coating mesh frame on the rubber sheet, and stick the mesh side to the rubber sheet.

3,Put the film on the top of the mesh exactly (in order to prevent the film sliding, it is best to use a little transparent tape to stick the film and the four sides of the mesh together);Use a glass sucker to lift the glass and place it on the film;(This machine is not configured with the glass for transportation safety, users can configure locally according to the frequently used size, 4-5 mm glass plate is appropriate).

4,Move the machine to the top of the screen frame. The distance between the lower edge of the case and the screen frame is 3-5 cm.According to the actual exposure time of photosensitive adhesive to set the countdown time.

5,Turn on the power and start the countdown timer;

6,After the countdown, The timer beeps and lights off,remove the machine, take out the glass and film, exposure is completed.