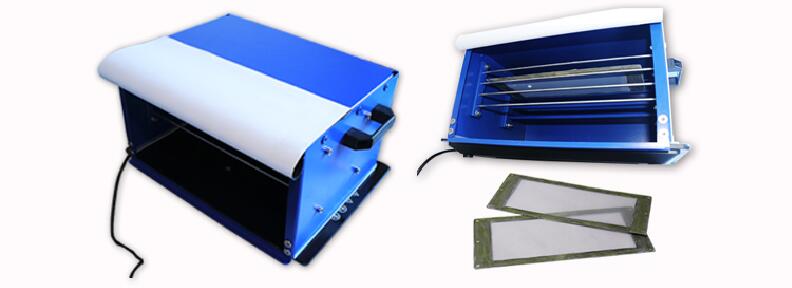

006601 SPE-BQM240 one color baseball cap soft caps screen printing machine

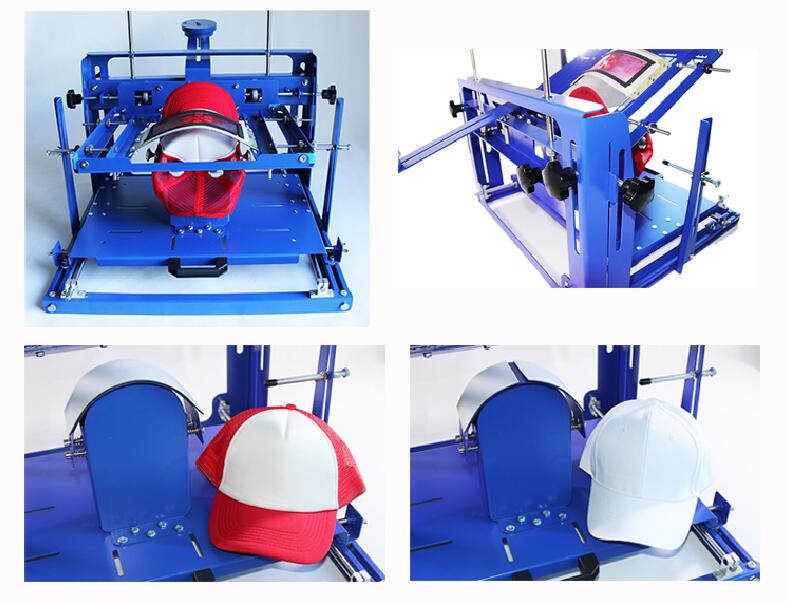

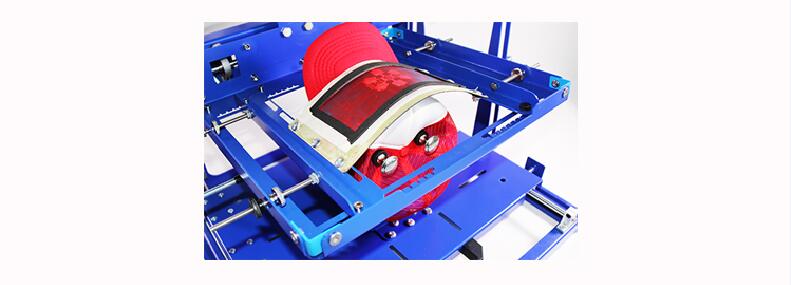

This machine is mainly used for the printing of various soft materials cambered surface and irregular cap mask ,such as cotton fabric, chemical fiber fabric, sponge, etc. For example, baseball cap, sun cap, duck cap, fisherman cap, leifeng cap, zhongshan cap, octagonal cap all kinds of soft material caps, as well as masks of various materials and so on, the use of this machine can effectively improve the printing quality, improve the printing efficiency.

There are many kinds of caps and masks, with different shapes and sizes. The printing position is not accurate because of the difficulty in positioning. The printing surface is cambered surface with various bending degrees, irregular bending, diverse cap shapes and other special characteristics. The difficulty in fixing the cap and fitting the camber screen plate for different cap bodies in printing results in the very low printing efficiency of such caps and the difficulty in guaranteeing the printing quality.

The screen printing machine designed by our company can basically solve the above two difficulties:

1.Positioning by adjusting the radian of the cap and mask: using the adjustable arc material ; adjust the radian of the arc according to the need;

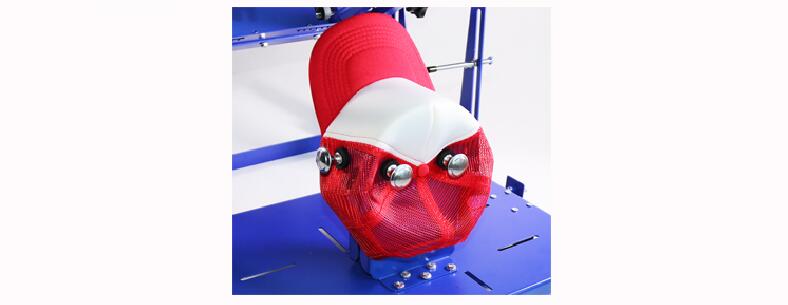

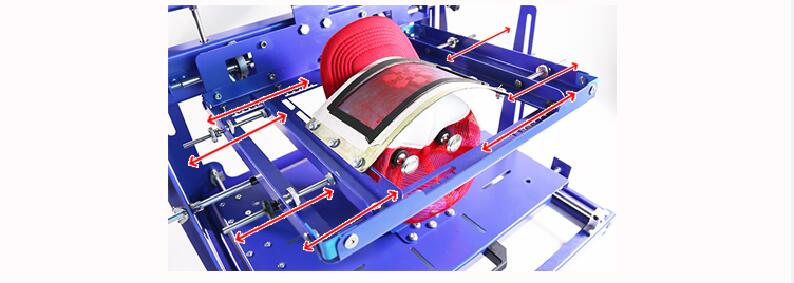

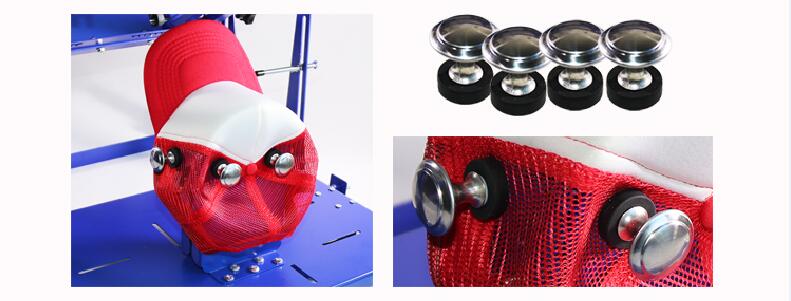

2.Positioning of cap and mask: place the cap or mask on the tooling, and position the cap and mask on the tooling vertical board by 4-6 magnets on three or four sides; The hat or mask will not move; Take off the hat just take off the magnet, convenient and quick; Easy to set the hat, the hat does not deviate;

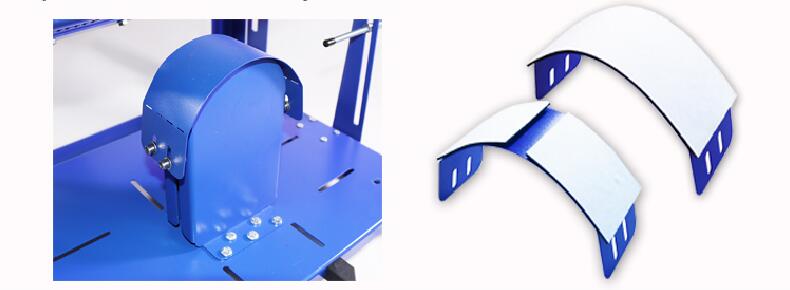

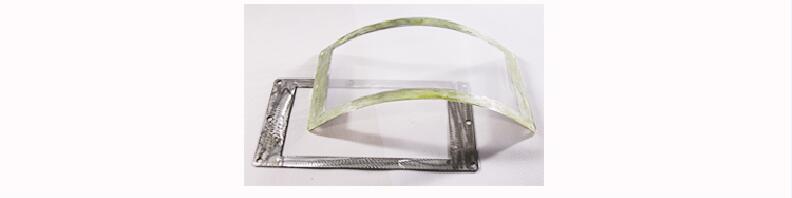

3.Stainless steel cambered plate can be bend a little from left to right in accordance with the arc of the hat ; To meet the radian requirements of the cap printing surface, so as to ensure that the screen plate and printing surface arc as parallel as possible, to ensure accurate printing positioning and the quality of printing.

Basic functions of the machine:

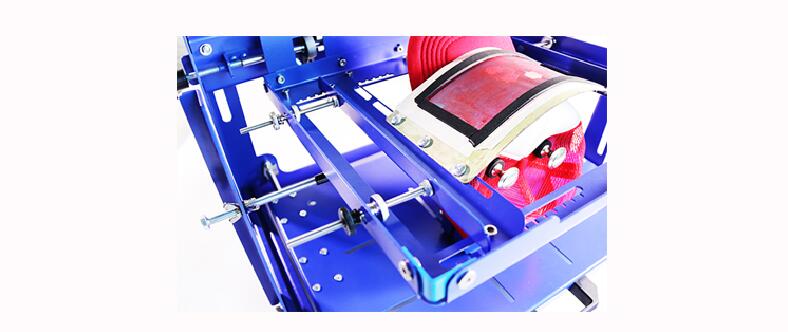

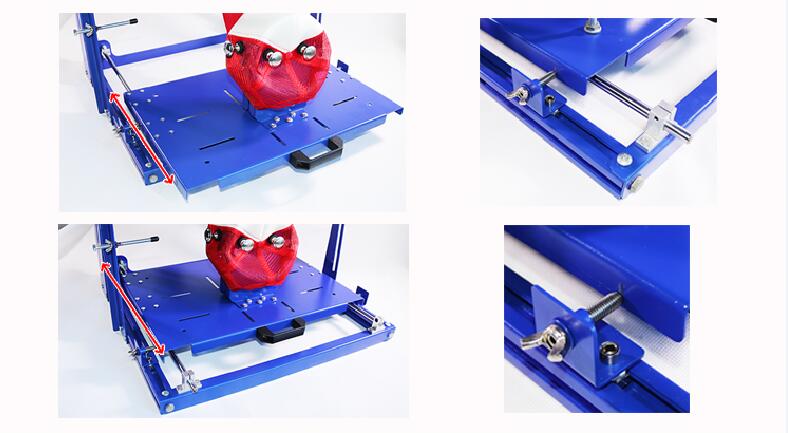

1.The bottom of the machine and the positioning platform can be moved back and forth, and a drag positioning device is set;Drag the platform out, cover with a hat or mask, and the magnet

adsorb to fix, push the machine to print; Pull out the platform, remove the magnet, remove the hat or mask; Pull out and push in can be accurately positioned by positioning ball screws on both sides of the platform;

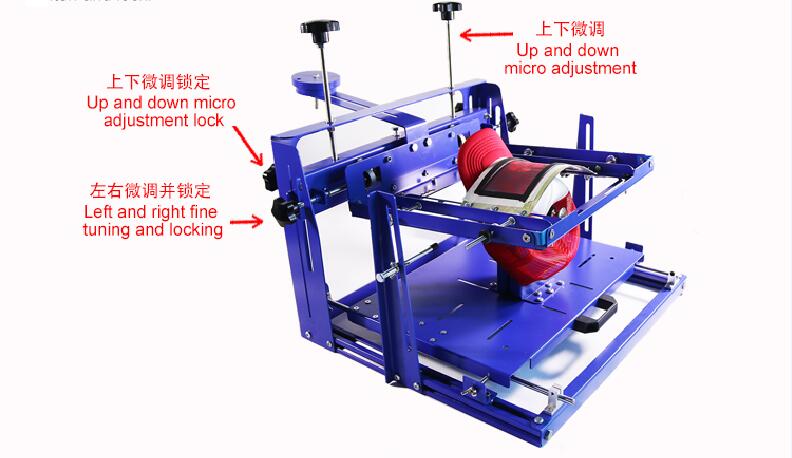

2.The main machine can be micro adjusted by manual knobs from left to right , up and down,up and down can move 170 mm; There is with a handle lock; Left and right can adjust 20mm,tighten and lock.

3.The machine adopts 1 mm stainless steel plate, the screen frame directly fixed on both sides of the frame beam; Screen plate can move 130mm front and rear; Screen plate installation beam

can finished by adjusting the screen radian by hand screw; After adjusting to the same radian as the printing surface, lock the screws at both ends of the two beams.

4.The whole magnet is covered with rubber layer, adsorption force is large, at the same time it will not damage the hat or mask; Magnet with handle, easy to access, fast, labor - saving.

5.The machine is equipped with two flexible stainless steel frames; Inner size is 100*190 mm (outer size is 130*200 mm); 100*240 mm (outer size 130*250 mm); Suitable for most kinds of soft hat printing patterns

6.All parts of the machine are advanced electrostatic spraying surface treatment, corrosion resistance, acid and alkali resistance, cleaning resistance, long - term use without rust.

Supporting equipment of the machine (optional according to the need, details of supporting equipment see the relevant webpage):

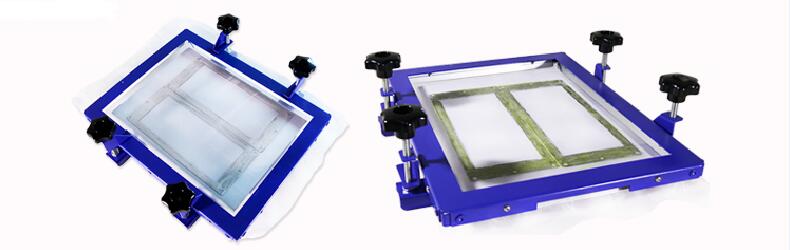

1.SPE-3040 special stretcher for arc-surface screen plate: due to the softness of arc-surface screen plate , normal stretcher cannot be used; This stretcher is specialized in stretching mesh of

arc screen plate; It can stretch 2 arc screen plates with the outer size of 130*250 mm at the same time.

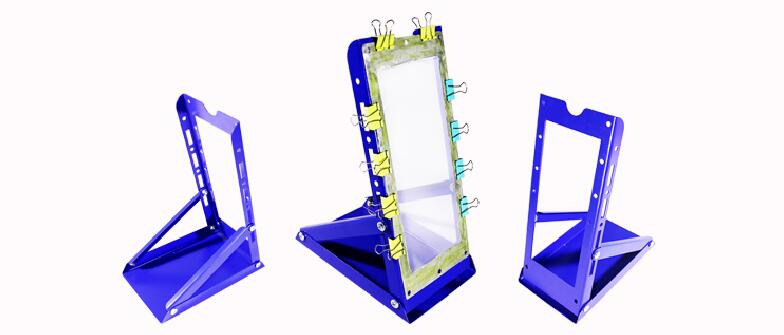

2.SPE- cambered screen plate special coating emulsion machine: because the arc screen plate of stainless steel only 1 mm thick, edge only 15 mm, relatively soft, traditional coating photosensitive emulsion can not ensure the smooth coating, the machine is specially designed for the arc screen plate, only used with the screen plate matching.

3.SPE-arc screen plate special drying cabinet: this machine is used for two purposes: one is specially drying the arc screen plate after degreasing and cleaning ; The second is used to heating the soft resin.

4.SPE-4632SBJ exposure unit: cambered screen plate can be suitable for a variety of exposure unit ; This exposure unit is not a special supporting equipment. This machine can place 3 cambered screen plate at the same time with the out side of 130*250 mm .

Usage methods and procedures (for reference only)

1.Drag out the platform, cover the substrate on the tooling and fix it with a magnet;

2.Adjust the screws on both sides of the cambered settings according to the radian of the substrate to achieve the condition that the setting and the cambered surface of the substrate basically coincide;Push the platform into the machine for positioning;

3.Install the screen frame with blank mesh on the frame rack;

4.Adjust the screen frame radian and cap printing cambered surface basically matched, and basically determine the printing pattern on the screen plate position;

5.Take down the screen plate and make plate according to the position of the pattern;

6.In order to prevent ink overflow, screen plate around can be affixed with sealing strip;

7.Install the finished screen plate and adjust it to the appropriate position ,Install the fixed screws on both sides of the screen plate to lock and print.

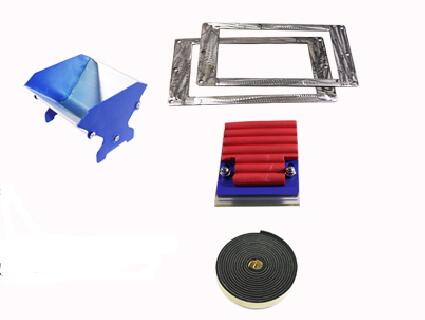

Configured with relevant tools and materials:

1. 1 piece 8 cm scoop coater

2. One for each of the two stainless steel cambered screen plates

3. 1 piece 8cm metal scraper (including rubber strip)

4. 1 roll screen plate edge sealing tape